What is ground balancing?

Ground balancing of a metal detector is the process of calibrating a metal detector to account for the mineral content and electrical conductivity of the ground in a specific area.

Different soil types and environments can sometimes affect a metal detector’s ability to accurately identify a target due to the ground’s mineralisation.

The ground balancing process essentially tells the metal detector to ignore or “ground balance out” the ambient mineral signals present in the soil.

This allows the detector to focus solely on detecting objects of interest like metal targets rather than getting confused by the ground itself.

Proper ground balancing is crucial because it improves target ID accuracy, increases detection depth capabilities and enhances discrimination performance.

Without ground balancing, a detector may struggle to differentiate desired targets from mineralised soil leading to excessive falsing signals or missed targets altogether due to noise.

Most modern metal detectors have some form of automatic or manual ground balancing feature that needs to be set appropriately for the specific conditions at a hunt site.

This can be in a form such as gradually adjusting manually until the correct balance is achieved, holding your finger on a button and “pumping” the coil up and down or adjusting a menu setting to track the ground conditions continuously.

Ground balancing is an essential step for optimal metal detecting performance in any environment.

Read my article on metal detecting for beginners and where to start here.

Unbeatable Multi Frequency!

You can now get the ultimate power of multi frequency technology over single frequency detectors with the Minelab Vanquish range of detectors.

The entry level Vanquish 340 now gives you ultimate depth, stability and sensitivity on all target types in every soil, including wet beach sand.

Not all metal detectors are created equal!

The ability to ground balance a metal detector is “usually” the preserve of mid-range to high-range detectors. Lower priced detectors as a general rule have a “fixed” ground balance setting.

Metal detector manufacturers often “fix” or preset the ground balance on cheaper, entry-level detectors to simplify operation for beginners and to save on costs.

A fixed ground balance means the detector is calibrated at the factory for average soil conditions. This eliminates the need for users to manually ground balance which can be confusing for new detectorists.

A fixed ground balance however can limit performance in environments with extreme soil mineralisation. More advanced detectors offer manual or automatic ground balancing to allow for better versatility across different terrain and conditions.

The latest metal detecting technology is multi-frequency where a detector uses more than one frequency to detect a metallic object. This itself massively increases it ability to cope with difficult ground conditions.

This used to be the technology you’d only find in top end machines but you can now get this powerful technology much cheaper and find it in entry level machines like the Minelab Vanquish.

You can read my article on multi frequency metal detector technology here.

Types of ground mineralisation

There are several types of ground mineralisation that can affect a metal detector’s performance.

Ferrous Mineralisation: Soils containing high levels of iron oxides like Magnetite or Maghemite can cause detectors to overload and report inaccurate target IDs.

Salt Mineralisation: Found in beach and saltwater environments, high salt content in the ground can lead to excessive falsing and depth loss.

Alkali Mineralisation: Soils with high alkaline mineral content like Limestone or Calcite can reduce detection depth capabilities.

Conductive Rock Mineralisation: Certain types of conductive rocks and minerals like Graphite or hot rocks can distort target signals. A “hot rock” can be described any highly mineralised rock that can give a metal detector an audible response.

Man-Made Mineralisation: Areas with high concentrations of buried metals, chemicals or even electromagnetic interference from power lines can impact detection.

Understanding the local ground mineralisation is key as different mineral types require different ground balancing approaches for optimal detector performance. Adjusting for the prevalent mineralisation maximises target ID reliability and depth.

Ultimate Tactical Packs!

Carry everything you’ll need for a detecting day like a First Aid kit, detector spares, finds boxes, batteries, snacks and drinks to rehydrate.

Never forget anything again with a belt pack!

When to ground balance a metal detector

There are several situations when you would need to ground balance your metal detector. We’ll cover these now.

At the start of a detecting session and in a new location: Different areas can have vastly different soil compositions and mineral content. Ground balancing is necessary to tune out the ambient mineralisation signals in that specific environment.

When soil conditions change: Sometimes, even within the same general area, soil makeup can vary significantly. If you notice a clear transition to a different type of ground, you’ll want to rebalance for the new mineral characteristics.

After switching detector modes/frequencies: Many detectors have multiple operational modes or frequencies. Changing modes often requires re-ground balancing to compensate for how that setting interacts with the ground mineralisation.

When detection stability diminishes: If you start experiencing excessive falsing, erratic target IDs or depth losses, it may indicate the ground balance needs to be reset or fine-tuned for the current conditions.

Essentially, anytime the detector seems to be struggling or you’ve moved to an area with potentially different soil properties, taking a moment to properly ground balance can restore peak performance.

How to ground balance a metal detector

Of course, all metal detectors are different and have differing user interfaces but essentially all work the same way. This can include manual adjustment, automatic adjustment or automatic ground tracking.

Firstly, always read your user manual for the specific way to carry out these operations. They will in most cases operate as I describe now.

You must also remember to find the nearest piece of ground with no targets in it or you could balance to a target or several targets not giving a true reflection of the ground.

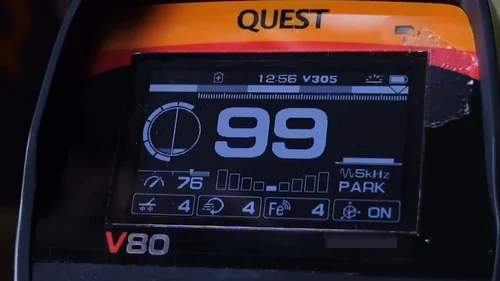

Manual ground balancing: This will involve pressing a button or two to enter into the ground balancing mode. On your control box, you will then make incremental adjustments using the “+” (plus) and “-” (minus) keys.

Whilst making this adjustment, you will be “pumping” the coil (raising and lowering) on the ground from say 1-2 inches to 6 inches and listening for when the two tones become the same tone.

If the ground balance is off, you will get either a high tone raising the coil and a low tone lowering the coil or (vice versa) depending if you have a “positive” or “negative” ground balance.

The goal is to raise and lower whilst making adjustments until the two tones become one tone. This is when you have perfect ground balance.

Auto ground balancing: This operation is essentially the same but you’ll probably press and hold the button down whilst pumping the coil until the tones become one tone. You then let the button go and you’re balanced.

Tracking ground balance: This will involve going into your menu system on your control panel and toggling on the automatic ground tracking.

Once switched on, the ground balancing can essentially be forgotten about as your detector will now periodically test the ground and automatically make any adjustments for you.

This does sound perfect but there are some things that need to be remembered when in this mode. When a target is found, you must keep the coil moving. If you slow your sweep down too much over a target, there is the possibility that it could think it’s the ground and track it out!

On older machines, you may get a knob labelled “Ground Balance”. This is the same albeit you gradually turn the knob until the two tones become one.

Ground balancing conclusions

Taking the time to ground balance your metal detector is one of the most important steps you can take for a successful metal detecting session.

By calibrating the detector to the specific mineral composition of the soil you’ll be detecting on, you ensure it can accurately identify desired targets without being confused by naturalised ground signals.

Proper ground balancing provides several key benefits. These include improved target ID reliability by reducing falsing and masking from mineralised soil.

You’ll also benefit from increased detection depth as the detector can focus on real targets. Better discrimination between good and unwanted targets like iron objects is also a benefit.

A perfectly ground balanced machine offers a more stable operation and gives consistent results across an area maximising detector performance for that environment.

Whether you’re a beginner or experienced detectorist, mastering ground balance technique is crucial. It allows you to take full advantage of your detector’s capabilities achieving more accurate and rewarding finds. Don’t overlook this essential step for optimal metal detecting success.

Good luck and happy hunting!

Unbeatable Multi Frequency!

You can now get the ultimate power of multi frequency technology over single frequency detectors with the Minelab Vanquish range of detectors.

The entry level Vanquish 340 now gives you ultimate depth, stability and sensitivity on all target types in every soil, including wet beach sand.